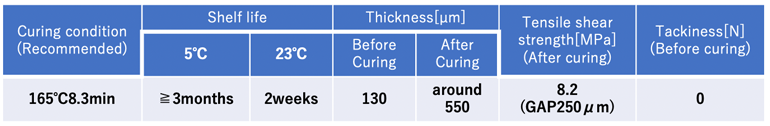

Thermal Foaming Adhesive Film for E-motor

Insulation and Fixing Flat Copper Coil in Stator

FEATURE

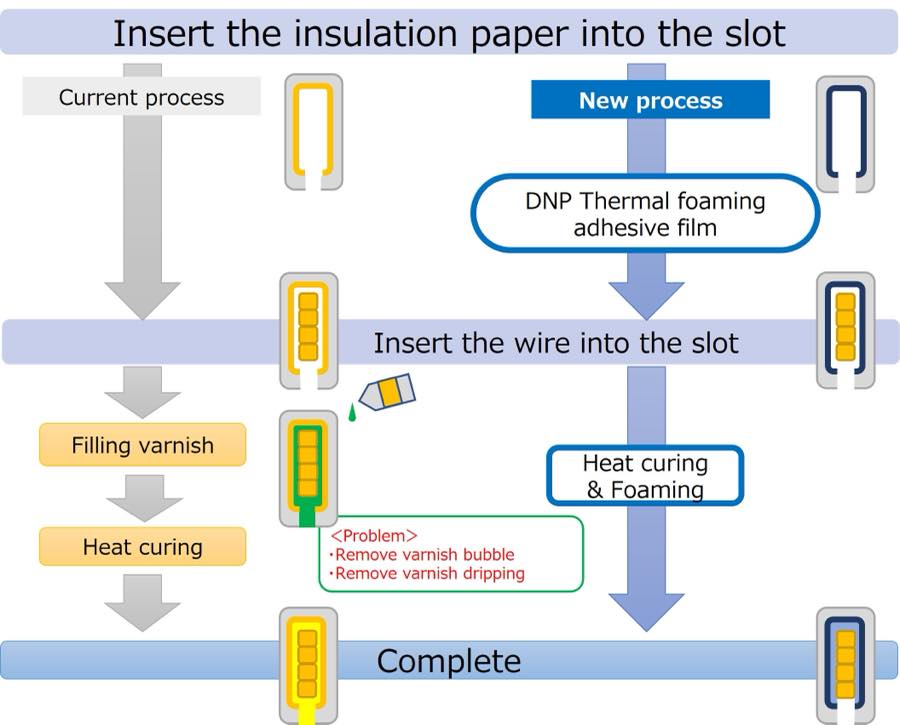

Insulation inside stator without varnish to improve production efficiency and reduce tact time.

- Foaming and adhesion occur at the same time through heating.

- Tackless and easy to insert in narrow gaps.

- Designed to prevent scratches and foreign materials from bending or cutting.

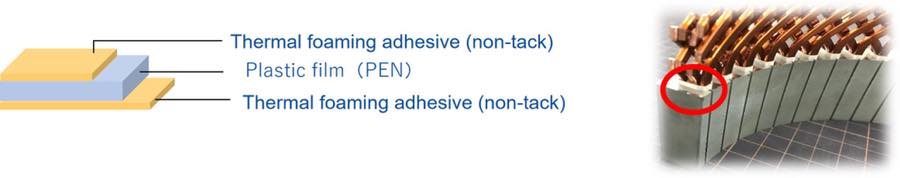

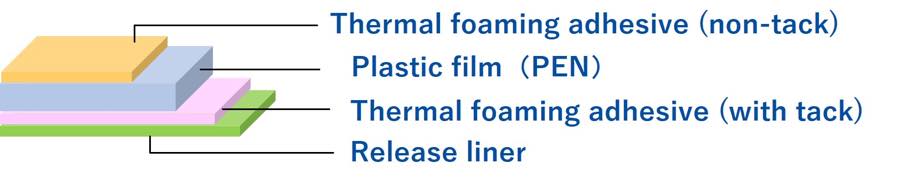

Curing condition:165℃x5min*(= retention time), Rate of temperature rise : 41℃/min.

*Including the temperature rise time, it takes about 8.3 minutes in total.

Tensile shear strength:single lap shear, Test speed:10mm/min, Adherence: SPCC-SD

Tackiness:JIS Z3284

simplify the process with our film

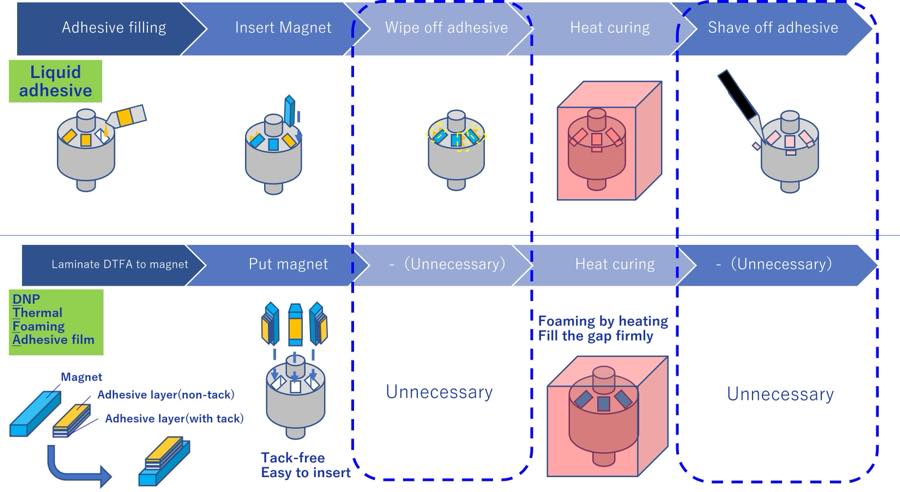

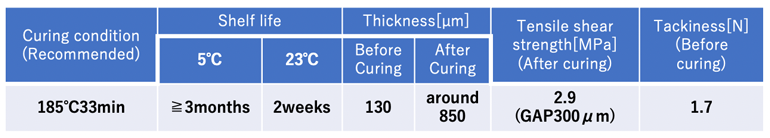

Magnet Fixing in Rotor

Features

Fixing magnet inside rotor without liquid adhesive to improve production efficiency and reduce tact time.

- Foaming and adhesion occur at the same time through heating.

- Tackless and easy to insert in narrow gaps (non-tack side).

- Good for temporary fixing (with tack side).

- Designed to prevent scratches and foreign materials from bending or cutting.

Curing condition:185℃x20min*(= retention time), Rate of temperature rise : 12℃/min.

*Including the temperature rise time, it takes about 33 minutes in total.

Tensile shear strength:single lap shear. Test speed:10mm/min、Adherence: SPCC-SD

Tackiness:JIS Z3284

simplify the process with our film